You are here

Electron beam evaporation for optical thin films

Electron beam evaporation (Alliance Concept)

Contact :

Alexandru TODORAN

TEMIS Sciences Building – Office N1-21

03 81 66 66 47 (Office)

03 63 08 23 77 (Deposition Area)

alexandru.todoran@femto-st.fr

Location :

TEMIS cleanroom

Deposition Area

Principle :

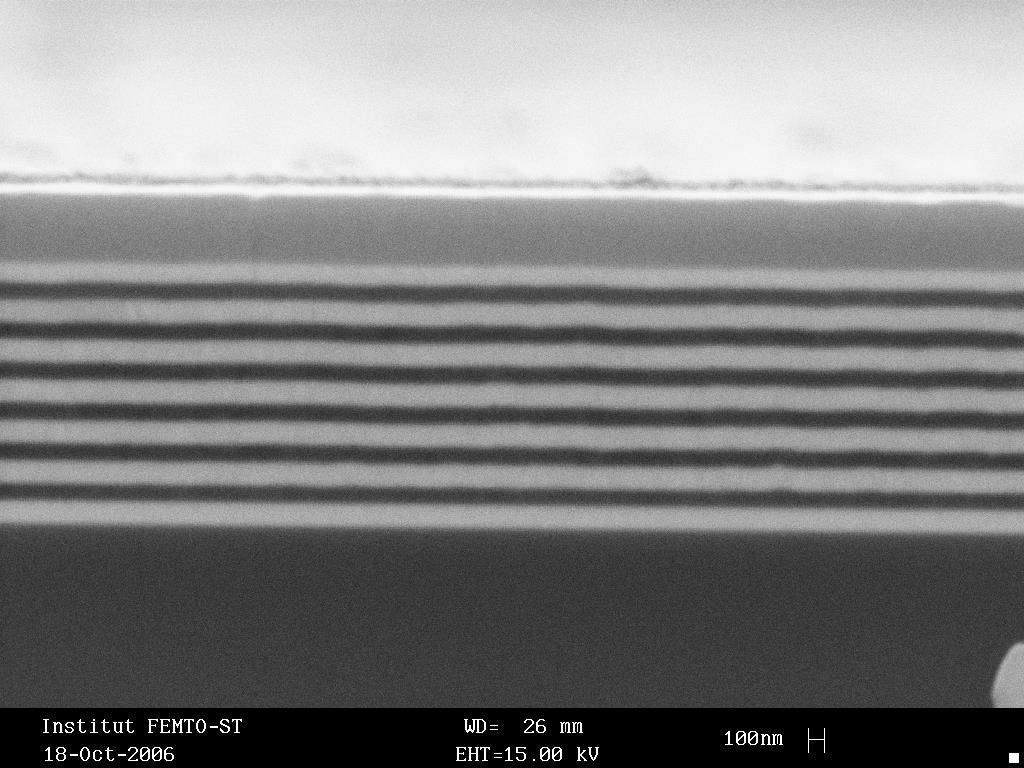

The material heating is performed by a focus electron beam and te film thickness is controlled in situ thanks to an integrated quartz balance. The achieved homogeneity is almost 4%

on a four inch substrate and the thickness accuracy is about 0.5 nm. This machine is specially adapted to multi-optical-layers used as

interferometric filters.

Technical characteristics :

- Gas : N2, Ar, O2

- Electron beam: 10 KW

associated with a 7cc crucible and 15cc crucible turret

- Rotary wafer holder : seven 3 inch wafers or five 4 inch wafers

- Sample heating : up to 280°C

- The chamber is heated at 60°C during the opening of the chamber

in order to avoid water absorption on the walls

- Turbomolecular pumping with bypass

- In situ control : Quartz controlled by a XTC/2

controller. The deported quartz enables to adjust the deposition

velocity before opening the shutter

- The installation is

entirely controlled by computer and it enables to realize

multi-preprogrammed-layers sets

Evaporated materials :

More frequently evaporated materials are Ti, Al, Au, Cu, Pt, Cr, W, SiO2, Ta2O5…..

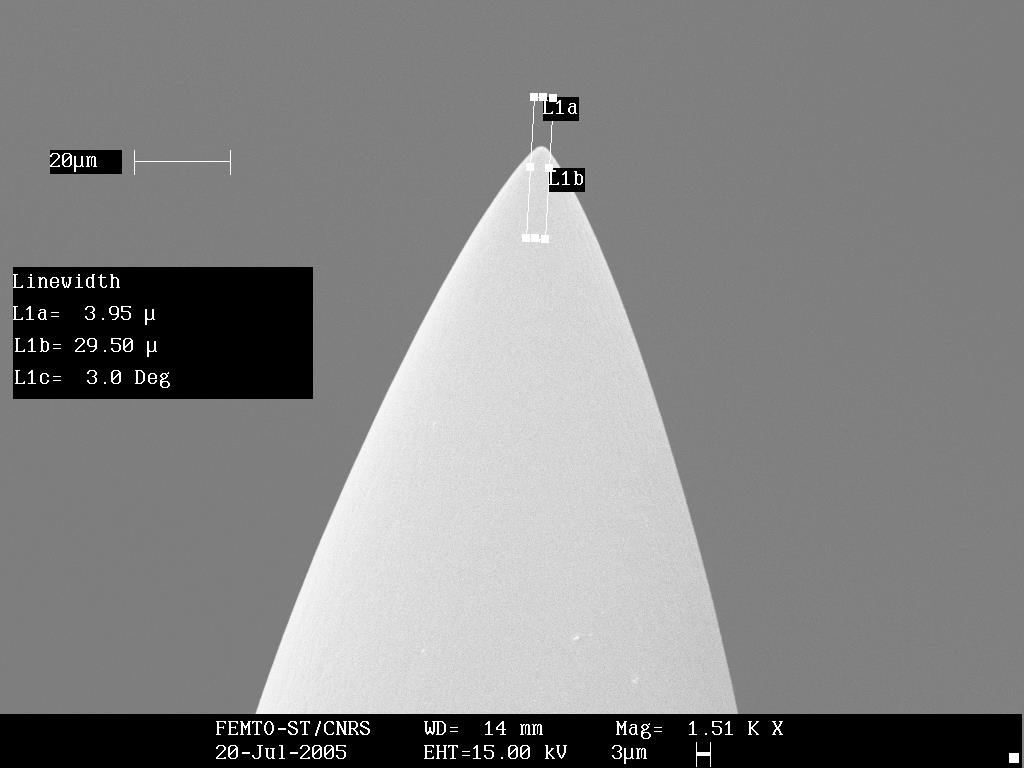

Achieved results :