You are here

Cathode reactive sputtering: PLASSYS

Cathode reactive sputtering: PLASSYS MP 450S

Contact :

Alexandru TODORAN

TEMIS Sciences building – Office N1-21

03 81 66 66 47 (Office)

03 63 08 23 77 (Deposition Area)

alexandru.todoran@femto-st.fr

Location :

TEMIS cleanroom

Deposition Area

Principle :

Using the addition of a reactive gas into Ar plasma, the machine allows to deposit composed layers as oxides and nitrures and notably this machine enables to produce aluminium nitride thin films.

Technical characteristics :

- gas : Ar, O2 et N2

- cathode : 6 inch magnetron

- supplying : Advanced Energy 1.5 kW

- substrate polarisation : RF 300 W max

- substrate holder : 1 sample up to 4 inch

- substrate heating : up to 800 °C

- charge lock

- secondary pump : cryogenic pump

Sputtered materials :

The sputtered materials with this machine are: AlN, TiN, TiO2 and SiO2

Achieved results :

References :

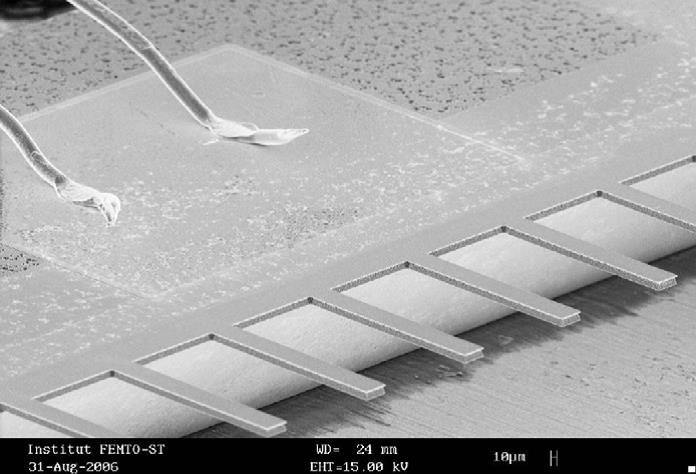

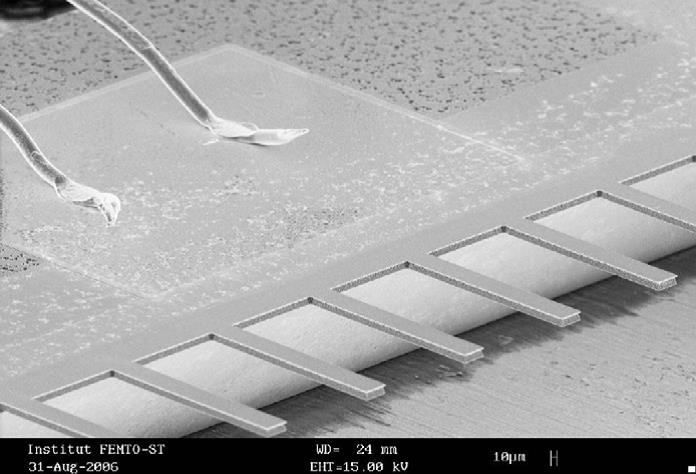

- Static and dynamic characterization of AlN-driven microcantilevers using optical interference microscopy

K. Krupa, M. Jozwik, C. Gorecki, A. Andrei, L. Nieradko, P. Delobelle, L. Hirsinger

Optics and Lasers in Engineering, Volume 47, Issue 2, February 2009, Pages 211–216

- AlN as an actuation material for MEMS applications: the case of AlN driven multi-layered cantilevers

A. Andrei, K. Krupa, M. Jozwik, P. Delobelle, L. Hirsinger, C. Gorecki, L. Nieradko, C. Meunier

Sensors and Actuators A: Physical, Volume 141, Issue 2, 15 February 2008, Pages 565–576