You are here

Deep Reactive Ion Etching Silicon (RAPIER SPTS)

Deep reactive Ion Etching Silicon (RAPIER SPTS)

Contact :

Djaffar BELHARET

TEMIS Sciences Building - Office N1-22

03 81 66 55 83 (Office)

03 63 08 23 74 (Dry Etching Area)

djaffar.belharet@femto-st.fr

Location :

TEMIS cleanroom

Dry Etching Area

Principle :

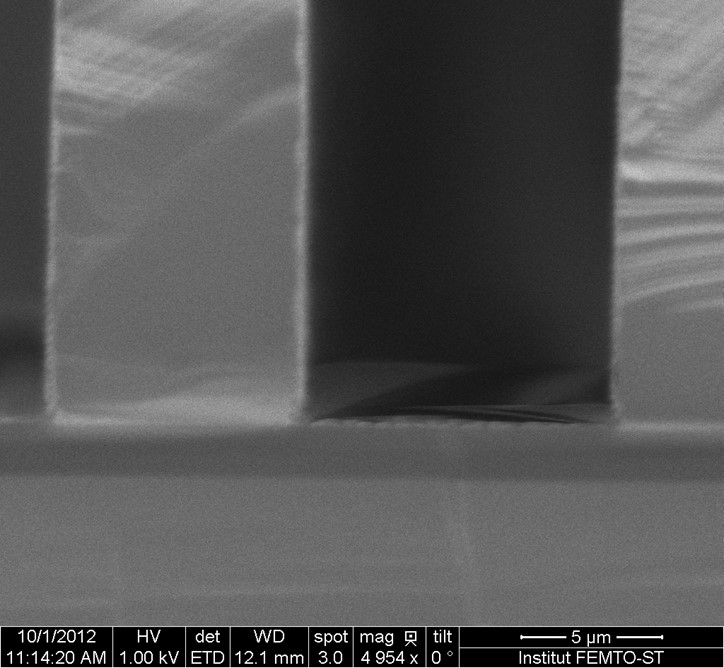

Silicon can be etched in an anisotropic (or isotropic) and dry way with

the technology called “deep RIE�?. This method combines deposition and

etching plasma assisted processes. While the silicon is etched, the

process enables to deposit a fluorinated component on the pattern walls

in order to passivate them. Etching-deposition cycles with given gases

and time enable to etch deeply and anisotropically the silicon

independently of its orientation.

Technical specifications :

- ICP source power : 5.5 kW RF

- Bias source power : 1.5 kW RF

- Electrostatic clamping with cooled wafer holder (0 to 40°C)

- Available gas : SF6, C4F8, Ar, He, N2 and O2

- Wafer size : pieces up to 4 inch

- Real-time endpoint detection system (Claritas)

Etched materials :

This machine is only dedicated to the silicon and silica (<1µm) etching.

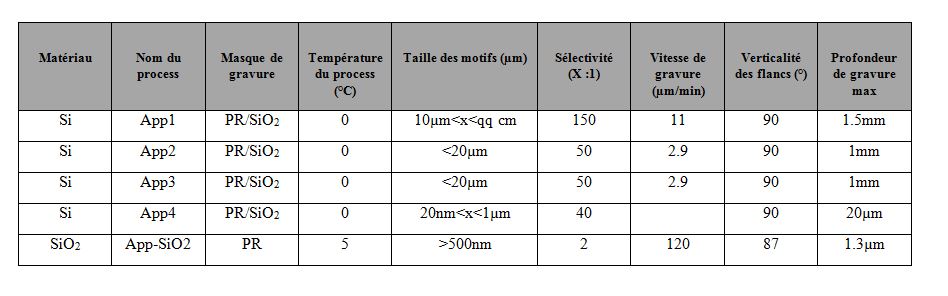

Table of etching performances :

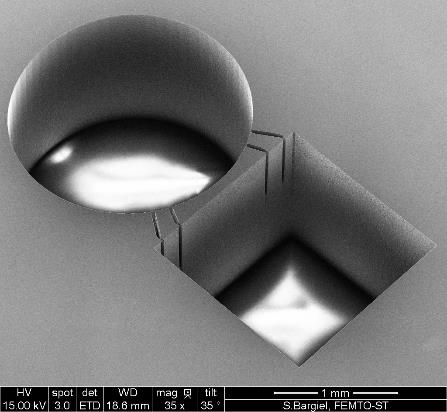

Achieved results :