You are here

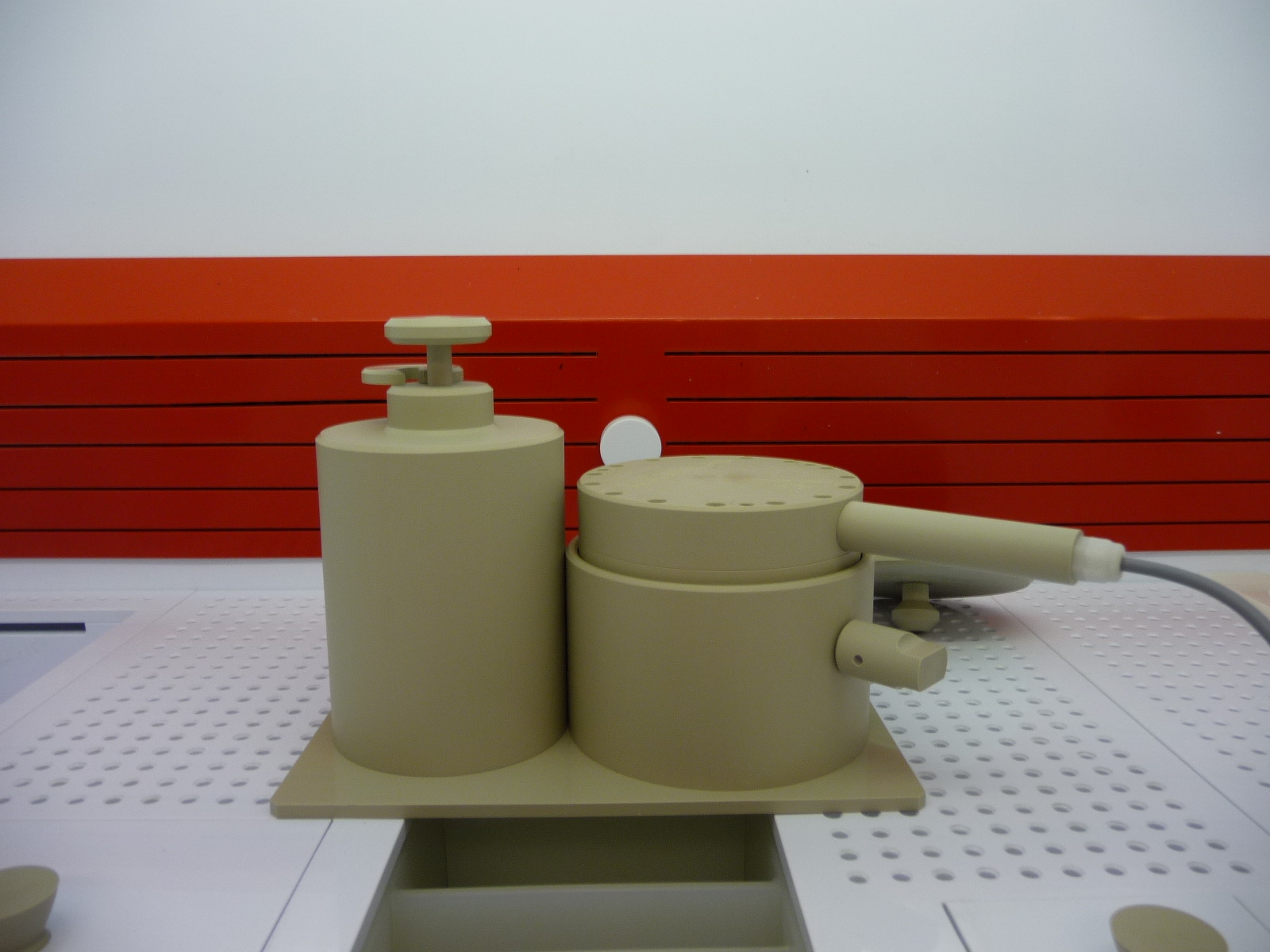

HF Vapor phase Etcher

HF Vapor Phase Etcher

Contact :

Laurent ROBERT

TEMIS Sciences Building – Office N1-21

03 81 66 66 47 (Office)

laurent.robert@femto-st.fr or tristan.faure@femto-st.fr

Location :

TEMIS cleanroom - Chemistry Area

Why ?

To release a fragile micro-device, which cannot be done in liquid phase, without using water rinsing or drying.

Principle :

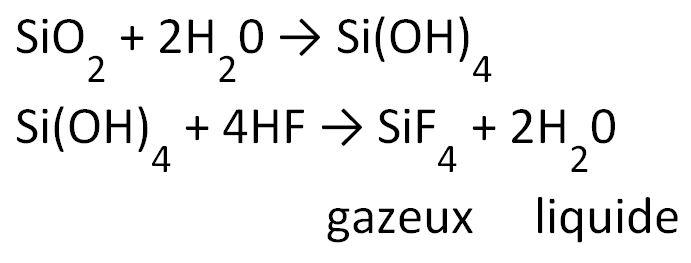

A sacrificial layer of silica (Si02), positioned under the device to release, is chemically etched in dry phase by means of hydrofluoric acid vapor (HF). Generally, the SOI wafers are used in this technology.

Advantages: ease of implementation, one step, no bonding, no drying.

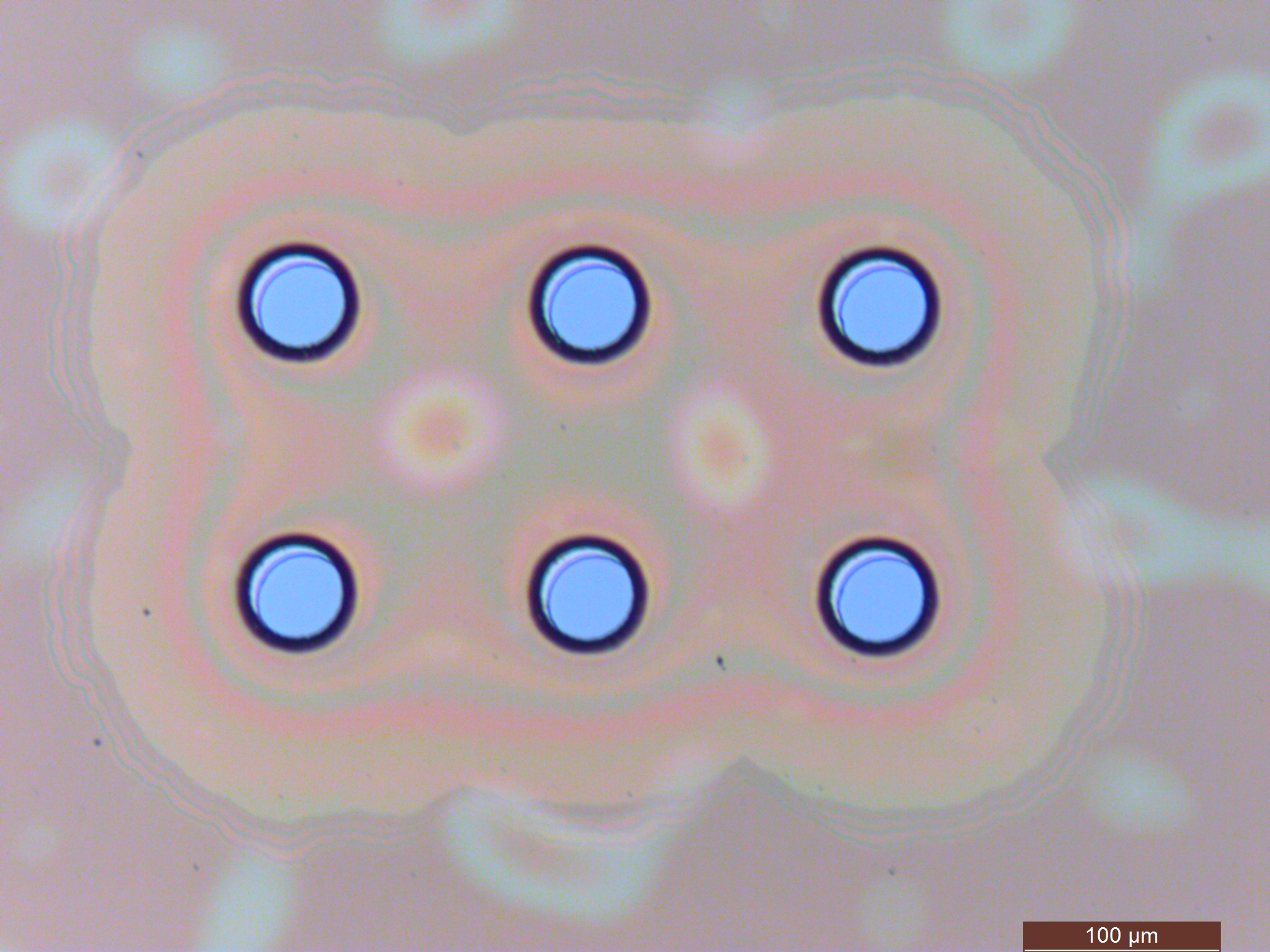

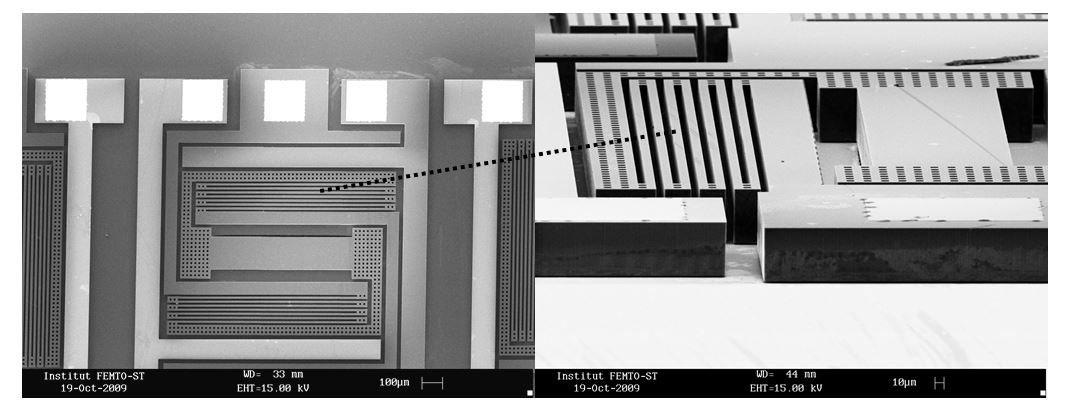

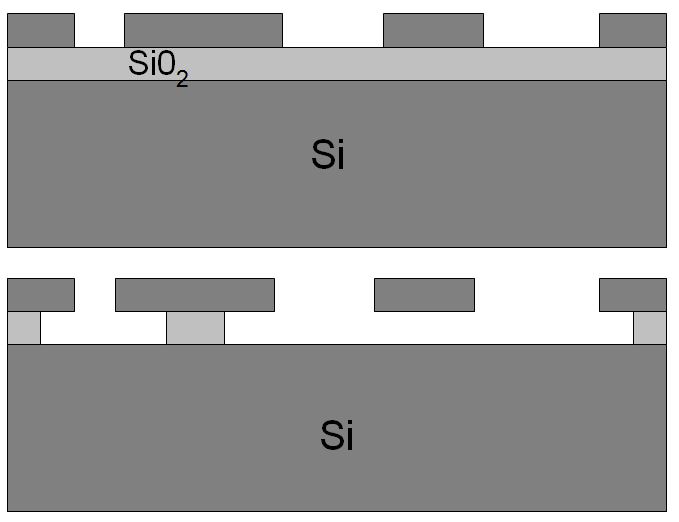

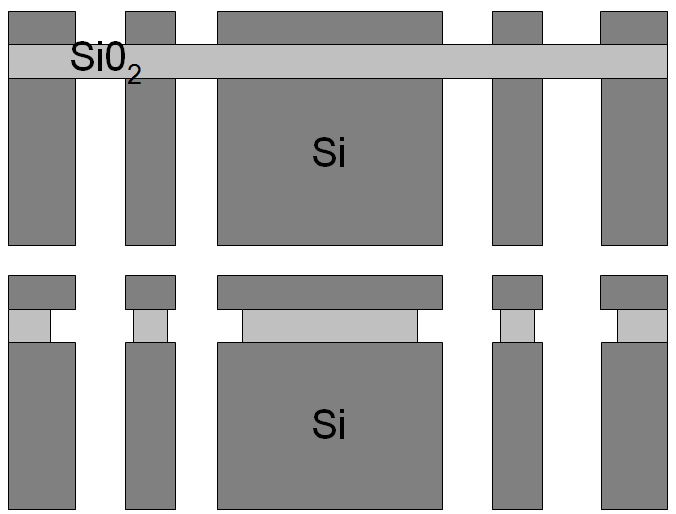

Two types of release can be used: by under-etching or by drilling.

Chemical reactions involved :

Water is both a reagent and a reaction product which may be responsible for bonding structures. For a totally dry etching, it is necessary to evaporate water as and when it is produced, so it explains why the sample must be heated.

Technical specifications :

- Heated wafer holder (35 to 60 °C)

- Electrostatic or mechanic clamping

- Maximal under-etching : 150 µm

- Under-etching rate : variable (typically 1 µm per minute for a silica layer of 2 µm)

- Used masks : Al, Au, Pt, photoresists

Use: safe because the operator did not enter contact with the HF liquid or vapor (devices placed in a bench with extraction). The wafer is first placed over the HF container (the wafer holder serving as a lid) and then the HF liquid is filled into the reaction chamberby the action of a valve.

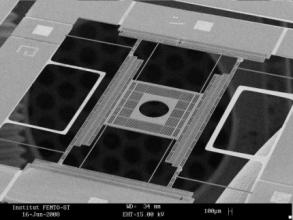

Achieved results :