µFab

Microfabrication Mécanique

Contexte

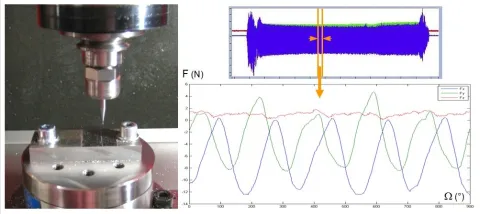

Le thème « Microfabrication » s’intéresse à l’analyse, théorique et expérimentale, et à l’optimisation des procédés de micro-fabrication par ablation de matière (µ-usinage). Les procédés de micro-ablation plus particulièrement ciblés par le thème sont le µ-fraisage, le décolletage de précision et la micro-électroérosion et ce principalement pour des applications faisant intervenir des matériaux durs ou difficiles à travailler.

Une particularité du thème concerne son ancrage industriel. Une grande partie des travaux de recherche sont menés en partenariat avec des industriels : fabricants d’outils coupants, décolleteurs, moulistes, fournisseurs de dispositifs biomédicaux , manufactures horlogères , lunettiers …

Objectifs et Thématiques scientifiques

Les objectifs sont multiples :

Il s’agit de définir et/ou d’optimiser une gamme de fabrication d’un composant micromécanique ou présentant des détails micro-géométriques fonctionnels. Pour cela il convient de définir ou d’optimiser : un procédé ou un enchaînement de procédés, la forme des pièces aux différentes étapes intermédiaires, l’outillage, le lubrifiant éventuel, la liaison pièce/machine, la liaison outil/machine et les conditions cinématiques (réglages machines et les trajectoires outil/pièce). Dans ce cadre les méthodologies de métrologie doivent être adaptées à la taille, au matériau et à la forme des pièces dans le but d’assurer le niveau de qualité attendu, que ce soit pour une pièce unique ou une série.

Les principaux thèmes scientifiques abordés pour satisfaire ces objectifs sont :

- Etude des interactions outils-matières aux petites échelles et en configuration réelle ou réaliste;

- Développement de pilotes expérimentaux et de méthodologies d’essais et de caractérisation adaptés à ces contraintes;

- Développement de modèles phénoménologiques et thermomécaniques permettant de comprendre et prédire le comportement des outils et des pièces produites, ainsi que les effets d’échelle associés;

- Optimisation des outillages, des opérations et conception des pièces micromécaniques produites;

- Hybridation de techniques de micro-fabrication (salle grise, salle blanche, dépôts) afin d’envisager la conception intégrée de microcomposants et l’optimisation multi-procédé;

- Proposition de techniques de micro-fabrication et de caractérisation transférables industriellement.

Savoir-faire

L’observation, l’expérimentation et la modélisation des opérations de micro-fabrication, telles que le µ-fraisage, le décolletage de précision et la micro-électroérosion nous permettent de comprendre les phénomènes mis en jeu, de pouvoir identifier des conditions de fonctionnement utilisables voire optimales, et de proposer en conséquence des stratégies de micro-fabrication adaptées au besoin. Le développement de modélisations et de caractérisations associées sont souvent complexes en raison des échelles d’observation, des effets d’échelle dans le comportement des structures et des matériaux, du confinement des zones de travail, des vitesses et des températures potentiellement élevées, de la présence habituelle d’un troisième corps fluide, de défauts géométriques et cinématiques, d’instabilités dynamiques, voire du comportement mécanique extrême des matériaux constitutifs des pièces et des outils. Le développement de cette activité s'appuie sur les compétences des membres du thème en mécanique des matériaux, identification, micro-fabrication, et caractérisation mécanique au sens large.

Mise en œuvre

Les activités du thème sont les moyens technologiques disponibles au sein du pôle Mise en forme du département et au sein de la plateforme MIFHySTO (Micro-fraiseuse Kern HSPC, Micro-fraiseuse Willemin W148, Machine µ-EDM SARIX SX-200 Dual, Décolleteuse Star SB12). Le thème a aussi recours aux moyens d’observation et métrologie sans contact disponibles au sein de l’institut (microscopie électronique, essais rhéologiques, mesures de vibrations, imagerie par caméra rapide, etc.).