Wire bonding machine

TPT 16

Semi Automatic Wire Bonder

Contact :

Franck LARDET-VIEUDRIN

TEMIS Sciences Building

03 63 08 24 22 (Office)

03 63 08 21 04 (Characterization-Packaging Area)

franck.lardet [at] femto-st.fr (franck[dot]lardet[at]femto-st[dot]fr)

Location :

TEMIS cleanroom

Characterization-Packaging Area

Principle :

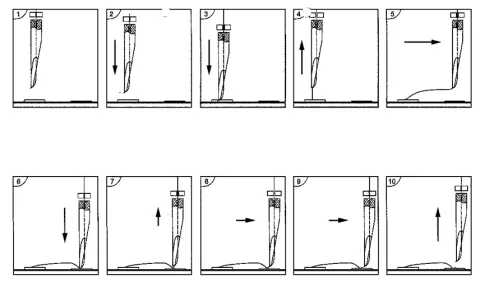

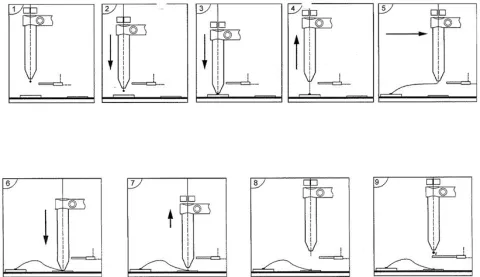

HB16 model is based on the ultrasonic wire bonding system. The bonding between two metals is obtained in combining a bond force, an ultrasonic energy and a time long enough to guarantee a metal-metal interdiffusion. Three wire bonding connection modes are available.

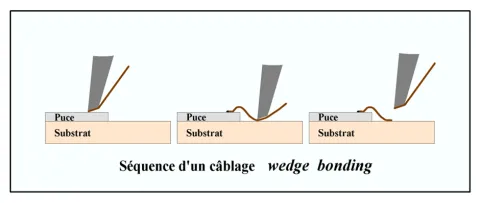

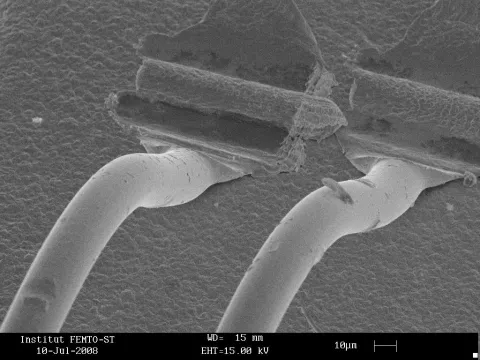

- Wedge/Wedge :

A aluminium wire is brought under the tool and then placed on the contact to be bonded. The wire is then guided by the tool on the second contact to perform the bonding.

This technique also enables the bonding of ribbons which can achieve more than 100 µm wide.

The bonding is performed at room temperature, so that the formation of intermetallic components (as purple plague) is prevented.

- Ball/Wedge :

A gold wire goes through a capillary. The ball formed at the end of the capillary (by an electric discharge) is bonded on a metallic contact. The capillary is then moved to perform a “wedge�? bonding. The wire is finally removed by the capillary and a new ball is formed for the next use.

Note: the substrate is heated between 80°C and 120°C.

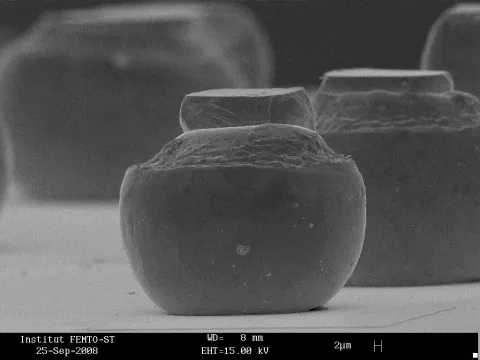

- Stud Bump :

This technique consists in dropping off the gold ball, generated at the end of the capillary, on the metallic pad and breaking the wire. A “tamping�? tool is then used to crush the residual wire and to create a flat surface on the top of the gold ball called “bump�?. It is one way to perform a connection by Flip Chip.

Specification needed to obtain a good connection :

- Metallic pad size on the chip and the substrate:

Minimal: 100µm - Recommended: 300µm to put three wires

- Metal to be used for the pads: aluminum, gold

- Metal thickness: 250nm min (surface as smooth as possible)

- We have equipments enabling to gild copper PCB (Printed Circuit Board).

Achieved results :

The main realizations consist in either connecting MEMS or MOEMS onto an electronic circuit, or putting them into TO-8-like or surface mount packages.

Comment :

This equipment is not self-service: a request on the cleanroom website is required.

To download the technical characteristics of the machine, click

[[{"fid":"1640","type":"media","view_mode":"default","attributes":{"class":"media-element file-default ext-link"},"fields":{"format":"default","alignment":""},"link_text":"here"}]]

.