You are here

Flip-Chip FC250

Flip-Chip FC250

Contact :

Sylwester BARGIEL

TEMIS Sciences Building

03 81 66 63 02 (Office)

03 63 08 23 10 (Packaging Area)

sylwester.bargiel@femto-st.fr

Location :

TEMIS cleanroom

Characterization and Packaging Area

Principle :

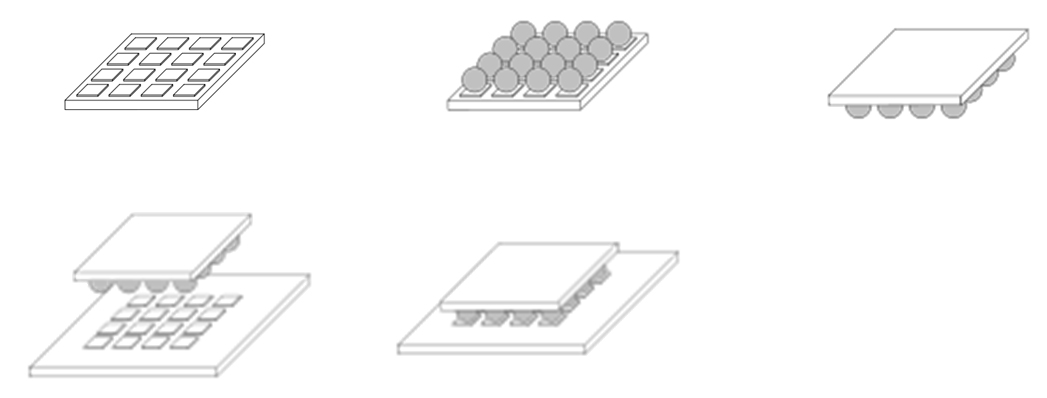

1/ Flip-Chip mode :

Flip-Chip technology corresponds to a direct electric connection of a chip face including the components, turned down (that is why it is called « flip ») on substrates or printed circuits by means of gold balls called Bump. The bonding is achieved by thermal compression.

The advantages related to this technology mainly come from :

- the performance increase

- the size: the whole surface of the chip can be used contrary to a wire connection with which the only perimeter is useful

- the robustness: it is the most robust mechanical interconnection method.

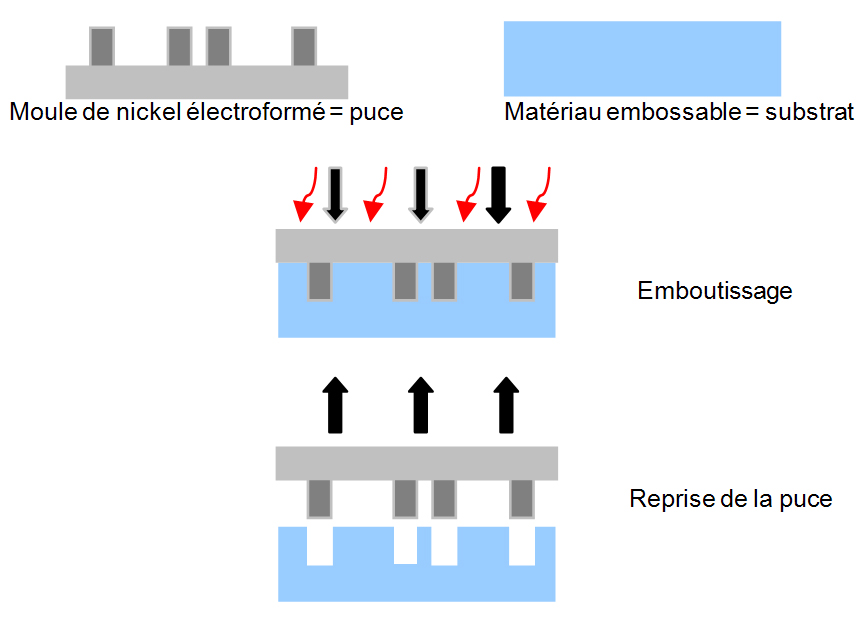

2/ Hot-Embossing mode :

On the same principle than before, after thermal compression, the chip is taken back by the machine’s arm, leaving its pattern in the substrate with which it was in contact.

3/ Dispenser mode :

The precision displacement of the chuck, combined with the dispense needle system fitting the FC250 upper arm, enables to dispense, depending on the predefined pattern, all products having an appropriate viscosity (glue, resist).

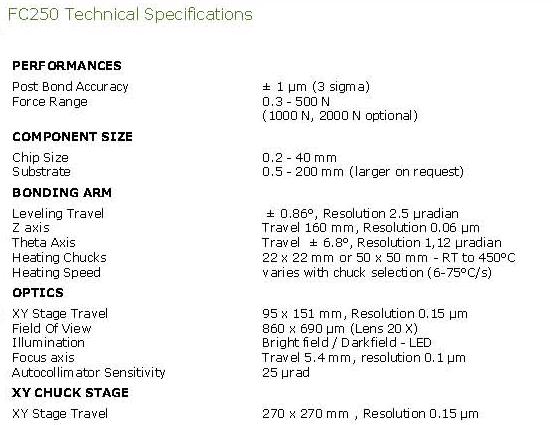

Technical characteristics :

The main characteristics are given in the following document

FEMTO-ST Institute has purchased a half-module of the FC250 version (from SET society) which, after modification, enables a manual process control more adapted to research developments. The alignment accuracy after bonding is +/- 1µm.

Comment :

This equipment is not self-service: a request on the cleanroom website is required.