You are here

ICP-PECVD SENTECH

SI 500 D ICP Deposition System

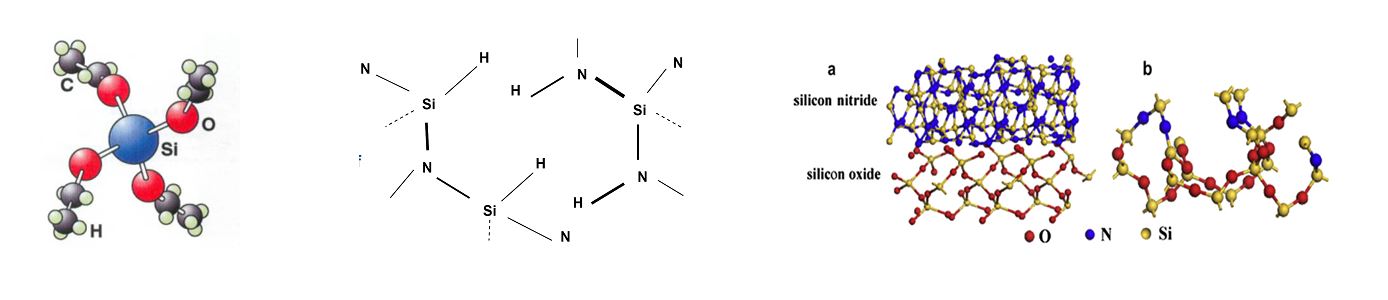

Deposition of silicon nitride, silicon oxynitride and silicon oxide

at low temperature by plasma deposition system

Contact :

Cyril MILLON

Bâtiment TEMIS Sciences – Bureau N3-12

03 63 08 63 02 (Bureau)

03 63 08 23 77 (Salle Dépôt)

cyril.millon@femto-st.fr

Localization :

Cleanroom TEMIS

Overview :

High-density

plasma technology is becoming increasingly attractive for the

deposition of dielectric films such as silicon nitride (SiNx), silicon

dioxide (SiOx), silicon oxynitride (SiONx) and hydrogenated amorphous

silicon (a-Si:H). In particular, inductively-coupled plasma chemical

vapor deposition (ICPECVD) offers a great advantage for low temperature

processing over plasma-enhanced chemical vapor deposition (PECVD) for a

range of devices including compound semiconductors (InP, GaAs ...). The

material properties of these films have been investigated as a function

of ICP source power, RF chuck power, chamber pressure, gas chemistry,

and temperature.

The ICPECVD films will be compared to PECVD films

in terms of roughness, homogeneity, refractive index, density and other

film characteristics. Compare to the traditional high temperature

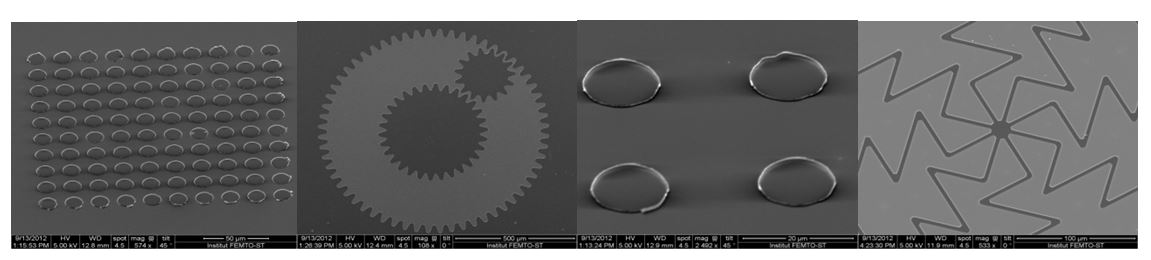

technology, the fabrication of MOEMS-MEMS/ NEMS and semiconductors at

lower temperature have many advantages (i.e. the co-integration).

The

SI 500 D plasma enhanced deposition tool is configured to deposit SiOx,

SiNx, SiONx, and a-Si:H films in a temperature range from room

temperature up to 350 °C with lower hydrogen content. The large range of

thin dielectric properties also allows addressing optical applications.

A brief insight into the possibilities of this kind of gases mixtures,

on thin layers properties with different stoichiometries, has been

investigated. A database is available at FEMTO-ST for the applications

in Optoelectronics, Microelectronics and Microsystems

DESCRIPTION and SPECIFICATION :

- Specification of gases process : SiH4, NH3, O2, Ar

- Vaccuum system : Pressure <10-6 mbar

- ICP source :

- Pressure: 1 Pa ...20 Pa

- Power: 100 ... 1200 W

- Plasma density: up to 5*1011 cm-3

- RF power supply : @13.56 MHz, 1200 W

Achieved results :

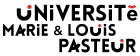

Lift-Off @ 80°C :

SiO2 with conformal coverage :

State of the Oxyde : SiO, Si2O, Si2O3, Si02

State of the Nitride : SiN, Si3N, Si3N2, Si3N4

State of the Silicon Oxyde nitride : Si2N0, Si2N02, Si2N2O, SiNO, Si2N03,Si2N3O