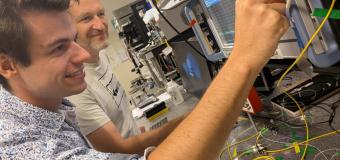

« Micron d’or » Award at the international microtechnology trade fair

For one of the most dexterous miniature robots with 7 degrees of freedom, allowing micromanipulation and microassembly in extremely confined spaces

This device is the first parallel robot integrating the gripping function, in addition to the six handling mobilities (three rotations and three translations). The movements in translation and in rotation as well as the closing of the terminal member (a clamp for example) are controlled by the movements of eight actuators fixed to the base of the robot. This arrangement allows great dexterity of movement in an extremely compact volume. This micromanipulator is intended for the industrial field to quickly handle products or components of small dimensions, for the medical to produce minimally invasive surgical instruments, or for applications with strong constraints (like manipulation in electronic scanning microscope or other nanomanipulation stations). Three demonstrators were realized to validate the concept with different technologies and different dimensions.The smallest demonstrator measuring 1 cm3 makes it the smallest robot in the world having 7 degrees of freedom.

Its structure was manufactured using a new process that was published in the Journal of Micromechanics and Microengineering. This method makes possible to integrate elastomer elements in a silicon structure produced in a clean room. The joints are therefore elastic, which eliminates mechanical play and dry friction.

The device was conceived and realized by researchers and engineers of nanorobotics and biomedical robotics teams from the AS2M department of the FEMTO-ST institute who are internationally recognized for their expertise in the fields of robotics for handling applications and automated assembly at micro and nano scales.

The project was financed in part by the Bourgogne Franche-Comté Council, the National Research Agency through the ROBOTEX equipment and the SATT Grand Est.

Contact : Redwan Dahmouche